19

2018

-

12

An important part of high temperature glass ink

Automotive high-temperature glass ink is mainly composed of glass pigments, ink adjustment, additives, etc. Compared with high-temperature glass ink, low-temperature ink is richer and glossier. High-temperature glass ink refers to coating on the inner surface of automotive glass after being treated with a high temperature of 600 to 700 degrees Celsius, which can effectively reduce the UV transmittance, thereby improving in-car comfort and car safety.

Automotive high-temperature glass ink is mainly composed of glass pigments, ink adjustment, additives, etc. Compared with high-temperature glass ink, low-temperature ink is richer and glossier. High-temperature glass ink refers to coating on the inner surface of automotive glass after being treated with a high temperature of 600 to 700 degrees Celsius, which can effectively reduce the UV transmittance, thereby improving in-car comfort and car safety.

Glass pigment, one of the important components of high temperature glass ink, is the key factor that determines the main properties of ink such as acid resistance, viscosity resistance, and shielding. Glass pigments are composed of low melting point glass powder and inorganic pigments, which are generally oxides. Low melting point glass powder enables ink to crystallize, crystallize, and form glass networks during high temperature sintering, giving high temperature glass ink resistance to viscosity and chemical corrosion.

Inorganic pigments are used to adjust properties such as crystallinity and system color. The melting point of glass pigments is slightly lower than the softening temperature of the substrate glass. When the glass pigments melt, the substrate glass just begins to soften, and the molten pigments penetrate into the glass to form a dense system, thereby achieving the desired performance.

By adjusting the ratio of various oxides, the softening point, thermal expansion coefficient, chemical stability, crystallization properties, melting temperature and other physicochemical properties of glass pigments can be controlled. With the improvement of industry standards, the acid resistance and viscosity resistance of high-temperature glass inks also require special design. Acid resistance is related to the reasonable ratio between each component, crystallinity, and compactness of the glass network.

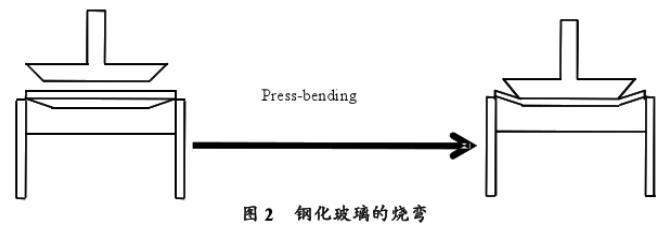

Some researchers also believe that the corrosion of acid solution to glass is that a large amount of H + penetrates into the glass solid structure, with the replacement of alkaline ions in it. Glass frit has a similar composition to glass, so it can improve acid resistance by preventing H + from penetrating or completely penetrating the sintered ink layer. Some researchers have introduced Nb2O5 into the glass pigment system to strengthen the glass network structure and improve chemical corrosion resistance. The tack resistance of high-temperature glass ink refers to the performance that when the ink is separated from the high-temperature resistant fibers coated on the mold surface during burning and bending (as shown in Figure 2), the ink does not stick to the surface of the mold cloth.

According to the crystallization principle of sintered glass, the crystallization rate of glass is related to temperature. During sintering, the outer surface temperature of the high-temperature glass ink is higher than that of the inner one, so that particles similar to the crystal core composition tend to migrate to the outer surface with high temperature to crystallize, thereby achieving the effect of anti-sticking.

Laizhou Resort Outward Bound Training

2017-12-14